Vacuum Form Panels

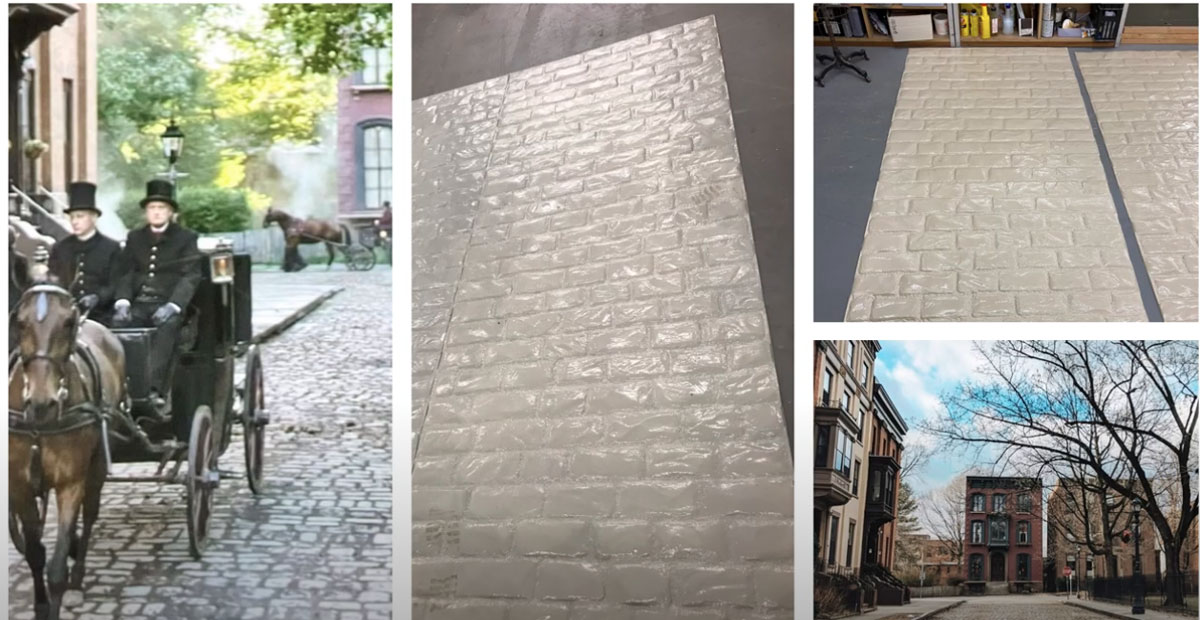

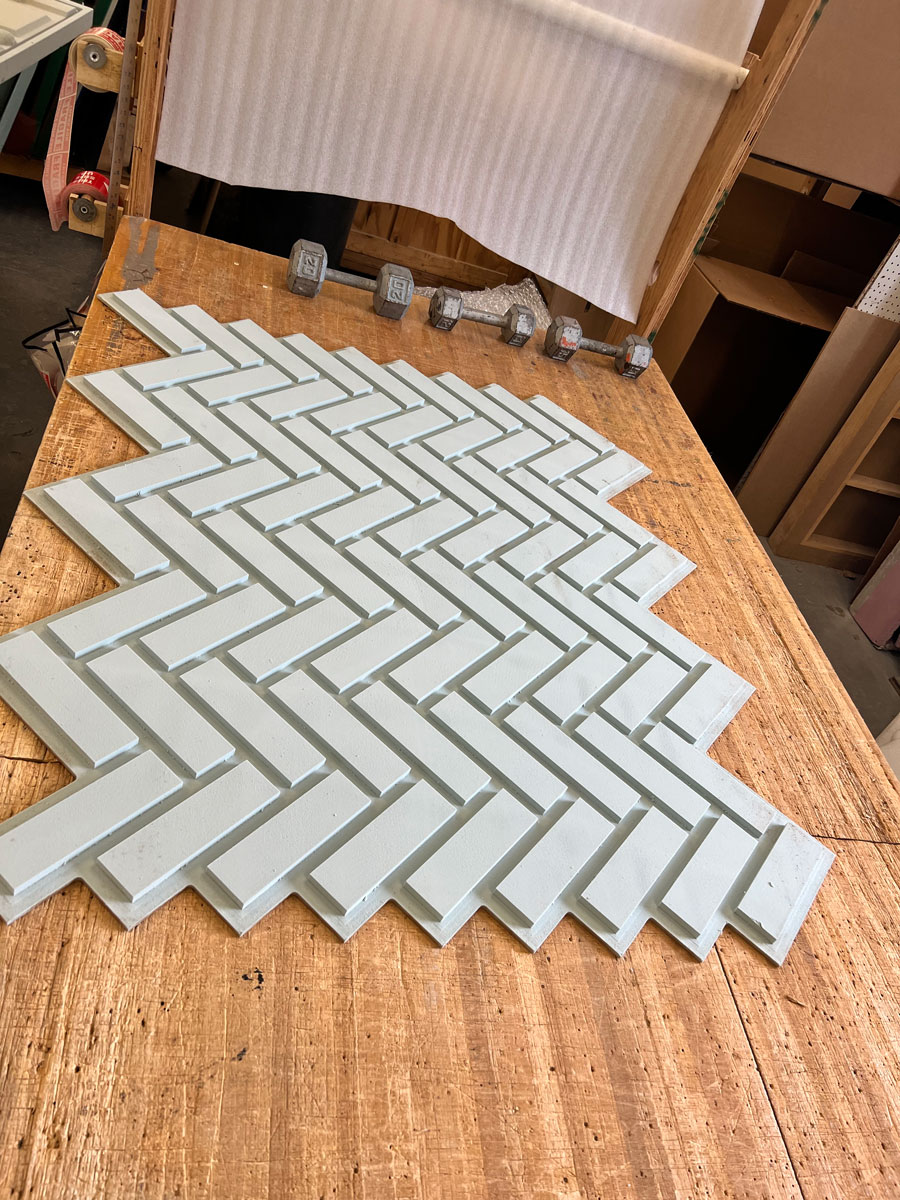

Vacuum forming is an easy and cost effective way to depict many architectural and design elements. Our line of stock vacuum form pieces consist of over 250 molds which include bricks, stones, building materials, decorative panels, windows, doors, props and much more. We keep many of our popular items in stock so they are ready to ship at a moment’s notice.

Custom Vacuum Forms

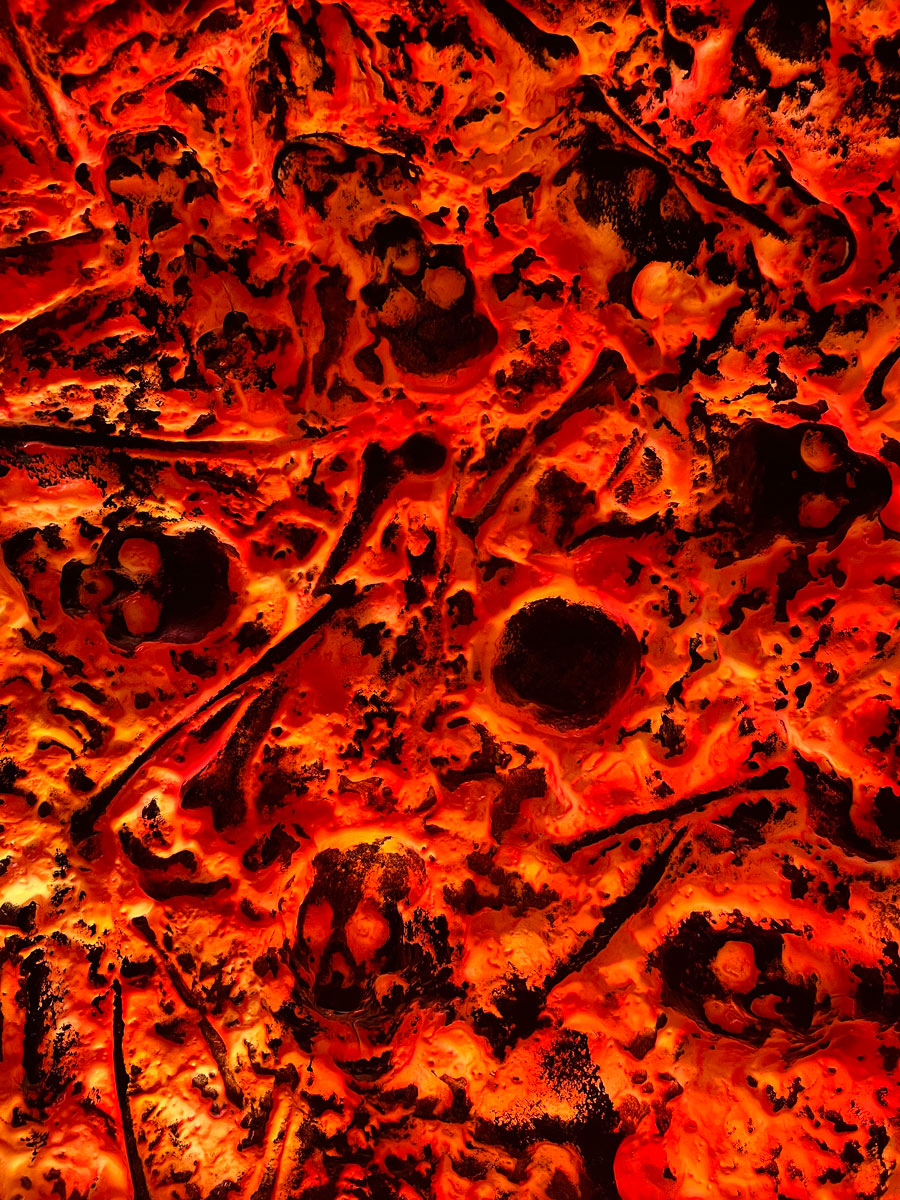

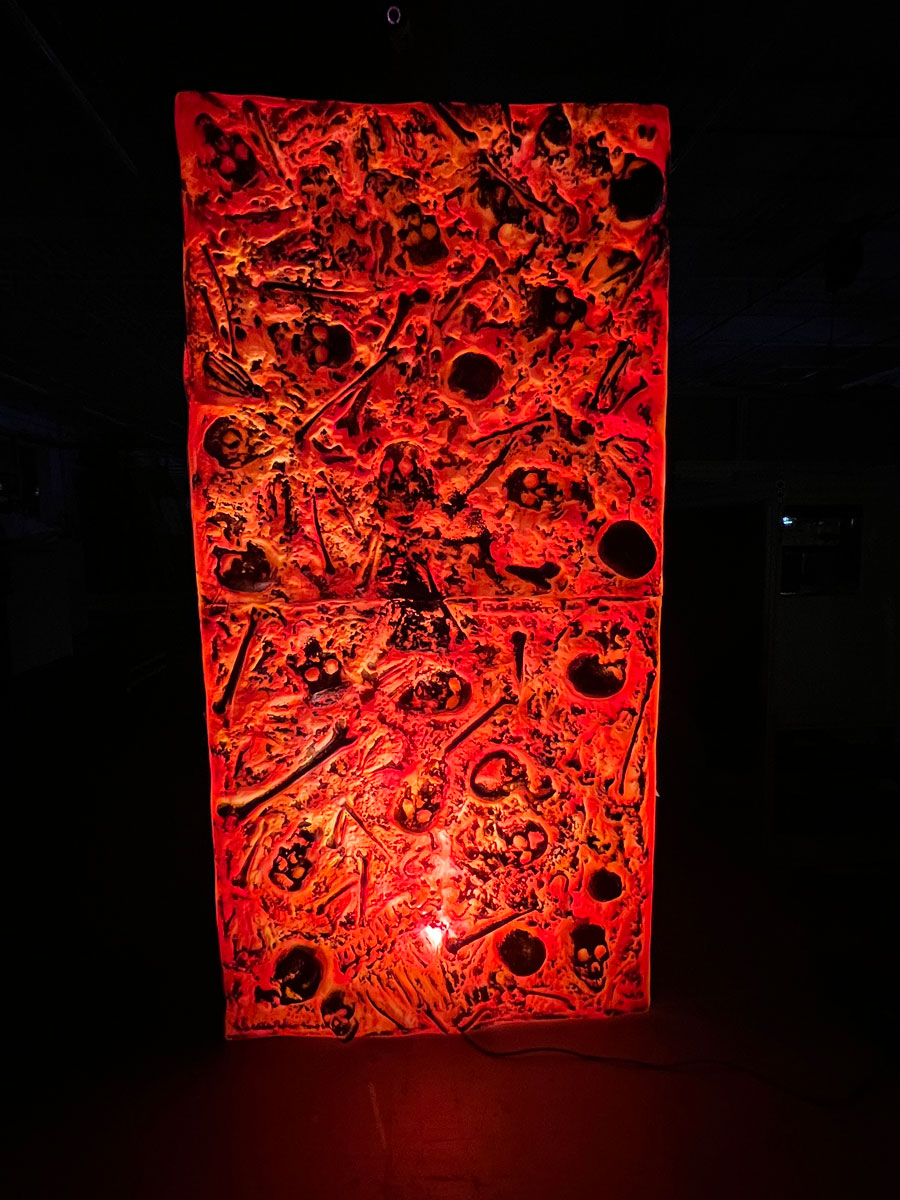

Provost Fabrication has a wide array of stock mold that can be seen in our catalog, however we also welcome the opportunity to design a custom product according to our customer’s needs. Provost Fabrication has the capabilities to take your design and bring it to life.

- Create a custom mold based on drawings and information provided by customer.

- Provide custom plastic including stock and customizable colors and textures. (most but not all require a minimum order)

- Trimming and assembly, if required is possible.

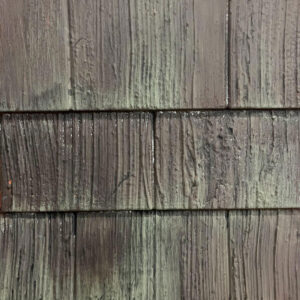

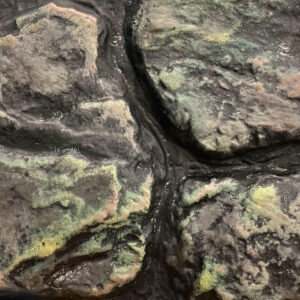

- Faux finishing to match your design.

- Create custom pieces from foam, rubber, fiberglass and other materials.

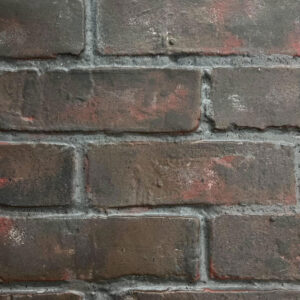

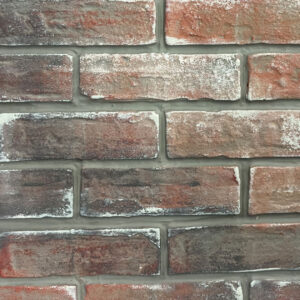

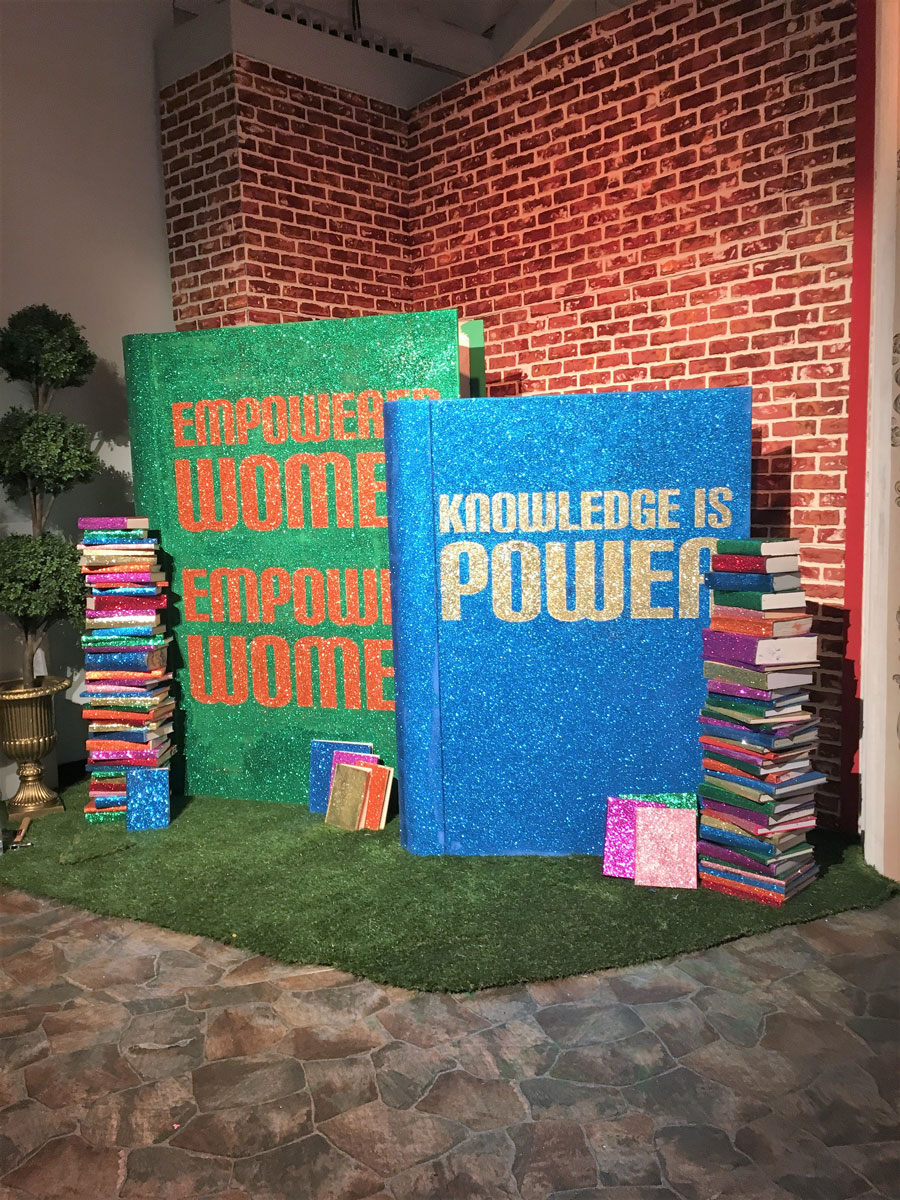

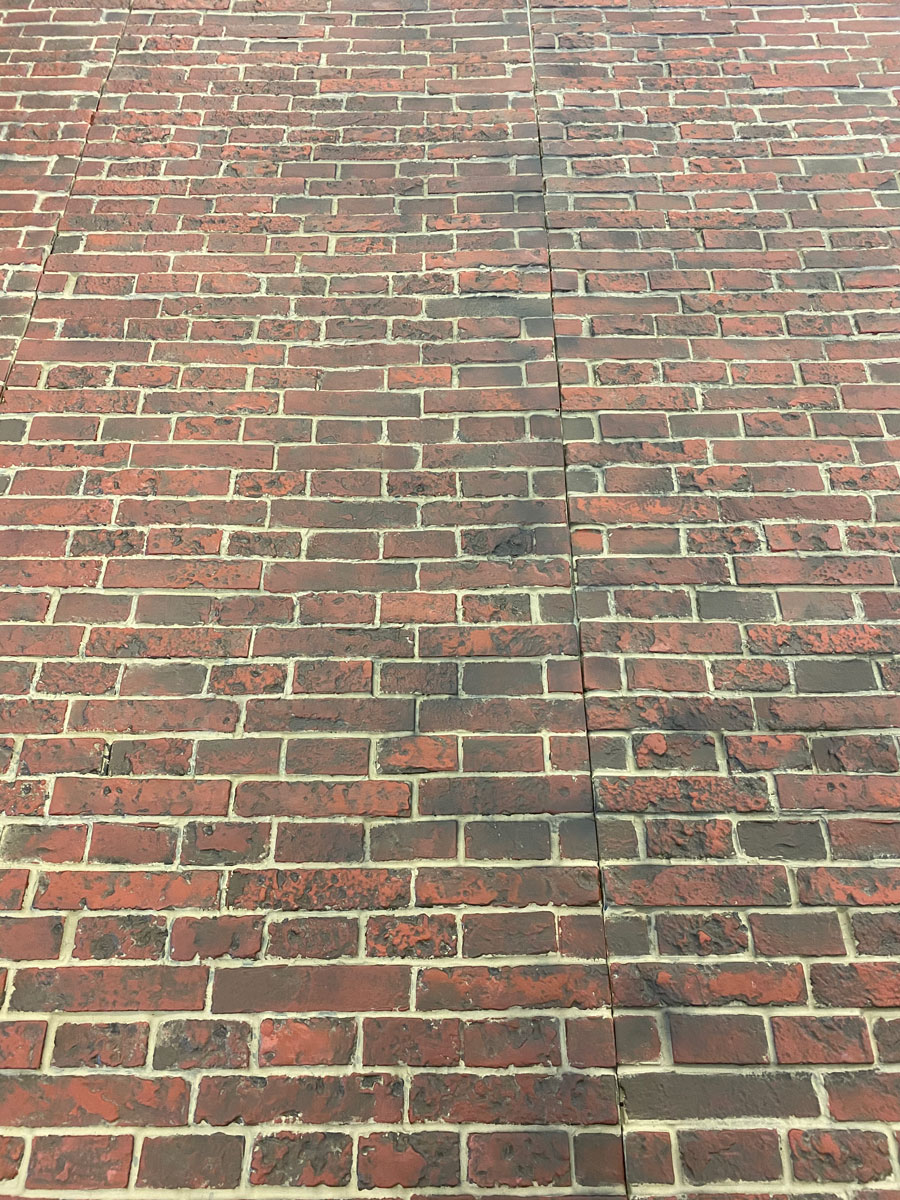

Painted Catalog Vacuum Forms

The Vacuform Brick is painted to look realistic with paint that is scratch and peel free. You can select from our paint samples, or we can provide a custom paint job based on your needs, with a quick turnaround time.

Faux Finish Painting Examples

The Vacuum Form Process

A “mold” (solid form with many small holes drilled in it) is made of the desired shape and placed on the machine’s bed (table). A sheet of thermo-formable plastic is secured to the frame of the machine which is then heated. The plastic sheet is heated until it is soft, pliable and reaches the optimal forming temperature. Once this occurs the plastic is rapidly lowered and vacuum suction is applied; pulling out the excess air while drawing the plastic tightly against the mold. Then rapid cooling of the plastic allows it to be released from the mold and retain its shape. The end result is a hollow duplicate of your mold. The possibilities are endless!

Below is a list of Available Materials. These are a few that Provost Fabrication works with regularly but we are always looking for new products to meet our customer’s needs.

Provost Fabrication keeps the following plastics in stock to insure quick turnaround times on orders.

- .015 mm Gauge PVC – White

- .030 mm Gauge PVC – Translucent, Clear or White

- .030 mm Gauge Kydex – Gray

- .060 mm Gauge ABS – White and Black

- .060 mm Gauge Kydex – Gray

- .060 mm Gauge HIPS – White

- .080 mm Gauge HIPS – White

- .090 mm Gauge ABS – White and Black

Provost Fabrication also offers additional special order plastics ranging from .015mm to .187 mm. Most are available in a variety of stock colors and can be manufactured with necessary Fire Ratings and UV Protection. Custom colors and gauges are available upon request. (Minimum orders required for some materials)

- Kydex Products

- Boltaron Products

- PETG (Vivak)

- Polycarbonate

- C.A.B

What are the advantages of using vacuum form panels?

Below is a list of benefits of using vacuum form panels from Provost Fabrication:

- Inexpensive Realistic Scenery

- Quantity Discounts

- Lightweight

- Waterproof

- Flame Retardant

- Easily Painted

- Easily Cut/Trimmed

- Recyclable

- Fast Turnaround Time

- Minimal Finishing

- Accurate Replication

How are vacuum forms made?

A “mold” (solid form with many small holes drilled in it) is made of the desired shape and placed on the machine’s bed (table). A sheet of thermo-formable plastic is secured to the frame of the machine which is then heated. The plastic sheet is heated until it is soft, pliable and reaches the optimal forming temperature. Once this occurs the plastic is rapidly lowered and vacuum suction is applied; pulling out the excess air while drawing the plastic tightly against the mold. Then rapid cooling of the plastic allows it to be released from the mold and retain its shape. The end result is a hollow duplicate of your mold. The possibilities are endless!

What materials are available for vacuum forms?

Below is a list of Available Materials. These are a few that Provost Fabrication works with regularly but we are always looking for new products to meet our customer’s needs. Provost Fabrication keeps the following plastics in stock to insure quick turnaround times on orders.

- .015 mm Gauge PVC – White

- .030 mm Gauge PVC – Translucent, Clear or White

- .030 mm Gauge Kydex – Gray

- .060 mm Gauge ABS – White and Black

- .060 mm Gauge Kydex – Gray

- .060 mm Gauge HIPS – White

- .080 mm Gauge HIPS – White

- .090 mm Gauge ABS – White and Black

Do you offer special order plastics?

Provost Fabrication offers additional special order plastics ranging from .015mm to .187 mm. Most are available in a variety of stock colors and can be manufactured with necessary Fire Ratings and UV Protection. Custom colors and gauges are available upon request. (Minimum orders required for some materials)

- Kydex Products

- Boltaron Products

- PETG (Vivak)

- Polycarbonate

- C.A.B